METAL- AND TOOL CONSTRUCTION WORKS

Manufacturing of tools for hot forging presses (horizontal), especially long lasting shearing tools. The supply of all new and remanufactured tools provides our costumers production equipment the maximum flexibility.

- Higher tool lifetime supplies higher productivity

Separated steps of the value chain can be outsourced towards our core competences.

WELDING CONSTRUCTION AND

WEAR- WELDING WORKS

Operating with deep knowledge in the welding division we can provide our customers a wide range of application fields. We use MIG – MAG, WIG and PTA technologies. If required we are also capable of automated robot welding processes to gain the best possible output.

The core competency of the Alois Müller company is to use different materials like Stellite, Durmat, Durolit, Stelloy, Corolit, Pearl, Höganäs … to supply tools with better wear conditions.

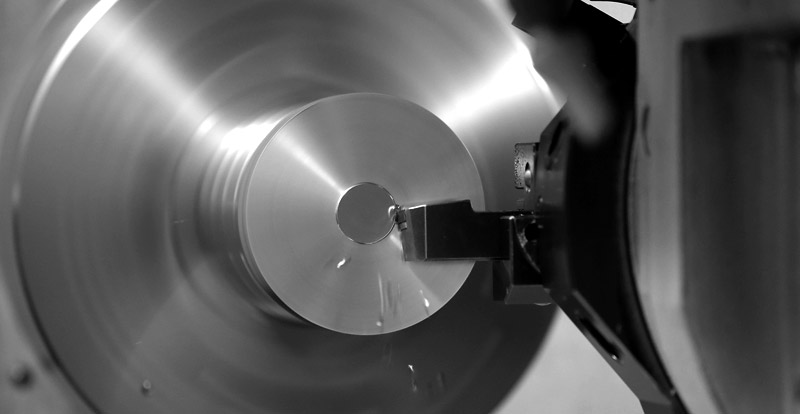

CNC – CONSTRUCTIONS

Turning, Milling (3 to 5 axis) and grinding with modern machinery and latest technological approaches.

We supply high precise cutting and grinding manufacturing methods.

Individual one piece constructions and series production based on customer requirements.

YOUR BENEFITS AT A GLANCE

// HIGHER TOOL LIFETIME

// SHORT LEADTIME

// COMPETITIVE PRICES

// INDIVIDUAL SOLUTIONS

// HIGH PRECISION WORKS

// RELIABILITY

// FLEXIBILITY

WHO WE ARE

As a modern and innovative company we offer advanced services, concerning welding constructions, metal – and tool constructions as well as CNC – manufacturing.

Based on a 170 years history and over 25 years of experience with high precise wear -/ welding solutions our customers can rely on our best quality standards.

We are certified with DIN ISO 9001:2015.

Our customers operate for example with:

- Hatebur – AMP 20, AMP 30, AMP 40, AMP 50, AMP 70, HM 35 and HM 75

- Sakamura – HNP, HBP, HPF, HF

// HOTFORMING TOOLS

// SHEARING DEVICES

// REMANUFACTURING OF TOOLS

QUALITY

LEAN STRUCTURES

We create further benefits for the customers by providing high flexibility in the processes and short lead times.

Costumers benefits is huge flexibility in the processes and short lead times.

ECOLOGICAL MINDSET

Throughout our sustainable use of resources and a high standard of social responsibility, we also secure and attach great importance to a highly ecological production.

One part of the actions towards a sustainable and future oriented production was the implementation of an efficient Solar system. 50% of the generated power is used in the own plant.

QUALITY STANDARDS

Our consistently high quality standards is a source for the success of the Alois Müller company and their partners.

The quality requirements of our costumers are the aim of our actions.

Our consciousness towards quality is shown by our DIN ISO 9001:2015 certification.

INDIVIDUAL SOLUTIONS

Throughout a transparent and open-minded communication with our interested parties, suppliers and customers a trustful cooperation is guaranteed.

We grow together in challenges and success. In doing so, we sustainably secure a competitive future.

CUSTOMERS SATISFACTION

The benchmark for quality is our customer. The evaluation of our products by our customers and their requirements are crucial for us.

Their quality standards go hand in hand with our delivery reliability.

IMPROVEMENT and INNOVATIONS

We see it as a task and a challenge to question the existing and to develop future-oriented solutions through continuous improvement processes.

This ensures that quality and competitiveness are continuously increased.

CONTACT

FEEL FREE TO CONTACT US

ADRESS

Alois Müller GmbH & Co. KG

Allmendgrün 2a

77799 Ortenberg – BW

made in Germany

BY PHONE OR MAIL

Phone: +49 (0) 781 42206

Telefax: +49 (0) 781 42205

mail@alois-mueller.de

OFFICE HOURS

Monday to Friday

7-12 a.m. and

1-5 p.m. or

via direct contact